WPC floor structure,WPC flooring is a new type of environmentally friendly wood-plastic composite material products, which combines the advantages of wood and plastic, with excellent physical properties and environmental protection features.

This flooring material is mainly made of plastic and wood fibers with a small amount of chemical additives and fillers, through a special mixing equipment, the production process of WPC flooring includes mixing wood fibers or wood powder with plastic particles, and then forming the flooring sheet through the process of heating, extruding and cooling.

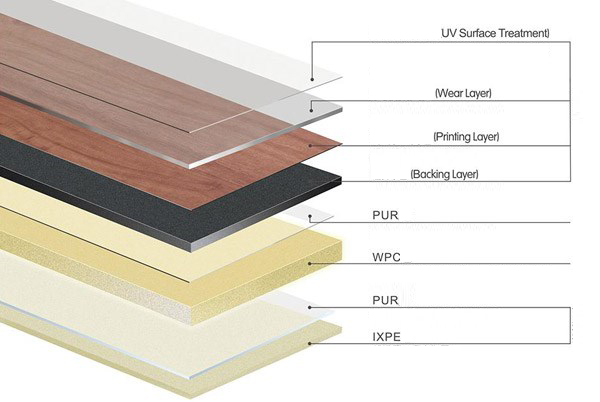

1, the structure of the WPC flooring: as shown in the figure, the Wood-Plastic Composite Flooring floor contains a paint layer, wear layer, color film layer LVT layer, WPC substrate layer.

2, WPC flooring components: Wood-Plastic Composite Flooring flooring main components and LVT flooring is similar, the biggest difference in the WPC material with the addition of foaming agent, so that the floor is lighter in weight, feel better.

3. WPC flooring production process: from the product structure diagram can be seen, WPC flooring for the inclusion of LVT and WPC substrate composite flooring.

The process is, first made of single-layer structure of the LVT flooring, and then extruded out of the WPC substrate with adhesive pressure paste composite molding, the adhesive used for the polyurethane class of cold-pressing adhesive.